Flowdrill

Since 2000 , Commerc Service, s.r.o. is exclusive representative of Flowdrill GmbH in Slovakia. Company Flowdrill is leading manufacturer of tools for termal / friction drilling and tapping.

Short description of the Flowdrill technology, process and tools:

Process:

The Flowdrill comes into contact with material using relatively high axial pressure and rotational speed. The generated heat makes the material soft and malleable enough to be formed and perforated. As the Flowdrill pushes into the material, some of the displaced material forms a collar arround the upper surface of the workpiece. The rest of the material forms a bushing in the lower surface of the workpiece. All this happens in a matter of seconds. The process does not disturn the material's internal structure. As a result, the formed bush is remarkably strong and can be used for bearing sleeves or producing a thread inside of it.

Application:

The Flowdrill process can be used in any application where the material thickness does not provide support for a threaded surface or a sleeve bearing application.BR Flowdrill tools can be used on standard drilling machines, NC or CNC systems.

Technology requirements:

Depend on used Flowdrill size, in general power from 1,5 up to 3,5kW and RPM in range of 1000 - 3500 will be enough for mostly all Flowdrill applications.

Advantages:

- Strong bush formed is up to 3 times the material's thickness and provide high strength pull out and high torque specifications

- Accuracy and Consistency - holes are exact with low tolerance divergences

- Clean and Environmetally Safe, No material chips are produced

- Fast Process - Cycle time 2 to 6 seconds

- Flowdrilling is suitable for a wide range of materials including mild and stainless steels, copper, brass and most malleable materials

- Will replace costly welded and riveted nut processes

- Flowdrill will improve your quality and save you a lot of time and money

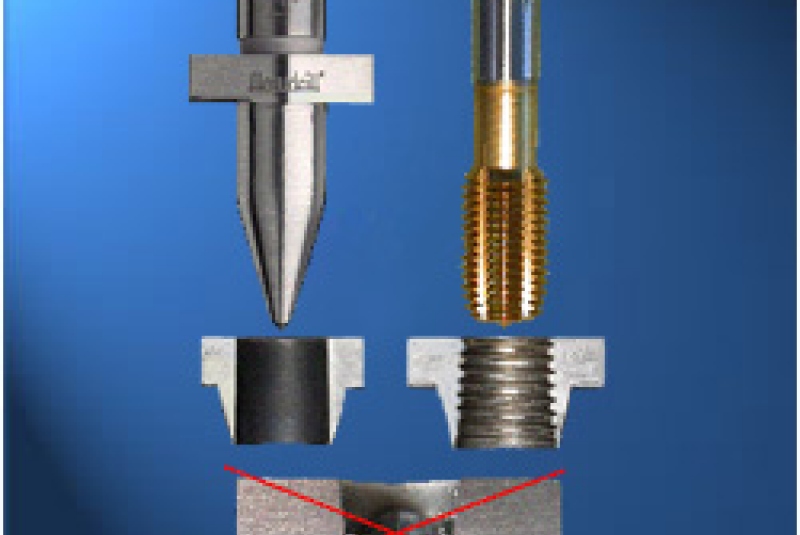

Flowdrill design

Flowdrill is polygonal tool which consists of the following parts:

- Flowdrill point

- Conical Section

- Cylindrical section

- Collar (type Standard) or Cutter (type Flat)

- Cylindrical shaft (h6)

Main types of Flowdrill tools:

- Flowdrill Short

- Flowdrill Short/Flat

- Flowdrill Long

- Flowdrill Long/Flat

- All above tools can have cutting tip at the Flowdrill point, these tools are marked REM

Note: It is also possible to produce special tools according to application or drawing .

For more detailed information about flowdrill, parameters and application examples go to: www.flowdrill-gmbh.de

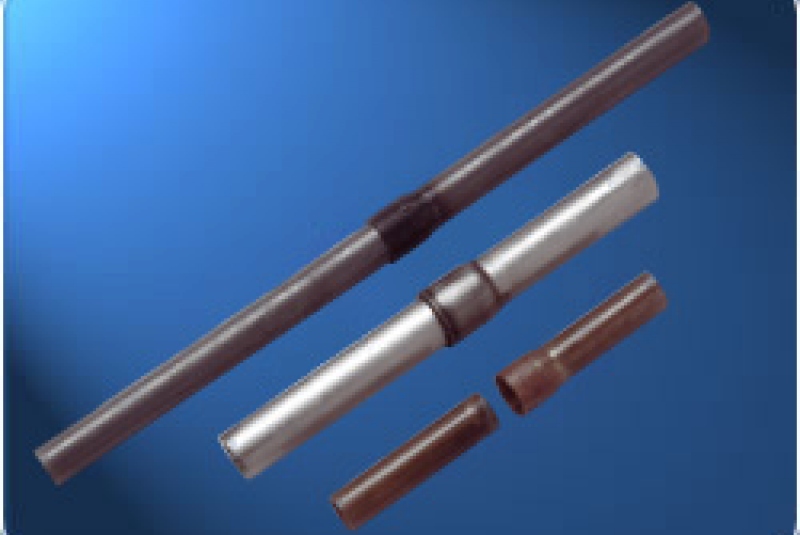

Flowtapping

As the cylindrical bush was created by hot forming (Flowdrilling) it is strongly recommended to make the thread by Flowtapping - cold forming of thread. Threads produced by Flowtapping have higher tensile strength in comparison with conventional threads and are more accurate.

| Flowtapping | Conventional cutting |

|

|

Advantages of formed threads - Flowtapping:

- no chips generated by Flowtapping

- higher RPM are used in comparison with conventional cutting

- significantly higher quality of the thread surface

- longer tool-lives, less tap breaks

- higher tensile strength and torque

- applicable on mostly all threading machines

- applicable for all Flowdrilled materials

Flowdrill application examples:

Due to capacity reasons it is not possible to provide all catalogues on this web, therefore please feel free to ask for them by e-mail or fax.

Please do not hesitate to contact our specialists in order to select the best tool for your application.